DESCRIPTION

Blancher-Cooler ThermoMaster has excellent energetic efficiency thanks to sophisticated system of product cooling and then preheating by cooling water ensuring recirculation of steam energy. The same way blancher achieves very low consumption of water. Blancher-Cooler have modular design, ensuring flexibility toward customer requirements regarding to capacity, further processing method or many other options. Using blancher with further freezing of product usually require much longer (more effective) cooling and preheating section. In offer is wide range of optional equipment for special product (spinach), or for simplifying of operation, cleaning etc.

OTHER SPECIFICATION

BLANCHER CONTAIN THIS MAIN FUNCTION COMPONENTS

ADVANTAGES OF BLANCHER-COOLER

OTHER SPECIFICATION

- Blanching zone.

- Cooling zone (multistage).

- Preheating zone.

- Water filter belt.

- Belt cleaning system.

- Infeed buffer with feeding belt providing unit for feeding and capacity.

- Electric system for fully automation of machine in operation and cleaning.

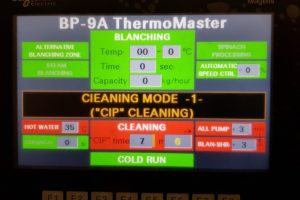

- 7″ touch screen graphic colouir display including temperature recorder.

- Independent temperature controllers with big digits.

- System for manual operation (for case of service or malfunction).

- System for locking of hot doors.

- Automatic cleaning CIP system for interior of blancher.

- Dewatering ventilator.

- Spinach processing devices.

- Platforms for operators, support frames.

- Uniform feeding of product.

- Excellent steam usage (… 8 – 16 kg of product per 1 kg of steam).

- Excellent water usage (… 0,5 – 1,5 litre of water per 1 kg of product).

- Automatic cleaning system CIP.

- Sophisticated software for CIP with lot of options (adjustments).

- Simple inspection and cleaning – big surface of doors. Whole blancher is easy to open. The doors 80% of surface from sides!

- Excellent thermal insulation with double doors (optional).

- Simple operation and maintenance.

- Compact design – simple transport and installation.

- The blancher machine is made of stainless steel AISI-304 (optionally AISI-316).

- Plastic product belt and filter belt with hygienic certificate under higher temperatures.

- All pumps and tubes are from stainless steel.

- Speed of belt regulated automatically according required blanching time adjusted on touch display.

- Infeed speed is regulated automatically from buffer according to adjusted capacity (kg/h) and may automatically adapt to level of product in buffer (if lower level, speed will reduce).

- Regulation of process temperatures fully automatic.

- Individually adjustable temperature for blanching, cooling and preheating.

- All waste water collected to one output point.